what to use on new m1 garand stock

Refinishing your M1 Garand Stock

Northew finishes can significantly amend the advent of your M1 Garand. This article volition cover one simple way to apply a new finish to your rifle stock. The rifle needs to be stripped and the wood prepared prior to applying a new oil to the woods. Beginning with the [ Detailed Striping your M1 Garand] and then the [M1 Garand Stock Stripping] article before continuing.

Oils? Stains? Varnishes?

The blazon of oil we desire to use to our burglarize stocks are known as drying oils. This is a poor description of what occurs to the oil. The oils don't actually dry by evaporation, instead, they cure past crosslinking in the presence of oxygen. The 2 oils that were used on the M1 during manufacturing were raw linseed oil and tung oil. Raw linseed oil is cold-pressed from the seed of the flax plant (Linum usitatissimum) and tung oil is pressed from the seed of the tung tree (Vernicia fordii). Each oil brings a unique character to the finished wood stock.

Varnish is a finish that is applied to wood to produce a hard glossy layer on the surface of the woods. Varnish might be colored or clear. Varnish is a more than fragile finish and may non be suitable in all applications.

A stain is ordinarily a pigment or coloring amanuensis suspended in a chemical binder. The deep red colour that older stocks develop is due to oxidation of the oil itself and is not a stain. The color of a stock with a stain applied tin can only fade with time when exposed to sunlight. The color of a stock treated with raw oil but improves with time and oxidation.

Linseed oil: And so many options, just ane existent choice.

Fiftyinseed oil is probably the near confusing of oils to cull from. This is due to several variations of the oil that are normally available. Linseed oil in its virtually pure course is pressed from the flaxseed and filtered. This oil is besides known as flaxseed oil. This cold-pressed oil is rich in fatty acids. These fatty acids are responsible for the deep red patina that develops on our rifle stocks with age. The acrid specifically responsible for this is linolenic acid. These fatty acids also dull the curing procedure making raw linseed oil ane of the slowest curing oils available. This unprocessed oil is the one we want to use on our rifle stocks to produce an accurate patina with time.

Raw linseed oil sold by many companies today isn't raw in the class we discussed to a higher place. This type of oil should exist called refined linseed oil. The art community effectually the 15th century began to seek ways to catechumen raw linseed oil into a form that didn't xanthous or change colors with time. This was important because the artists didn't want their colors to yellow with time. To accost the problems of yellowing the method of refining the oil was adult.

A process was devised where the fatty acids could be extracted from the linseed oil. Refined linseed oil is slightly faster curing than its raw form but will not develop the carmine patina with time. To add together to the confusion, products marketed by companies like the Sunnyside Corporation as "Pure Raw Linseed oil" are actually "Pure Refined Linseed oil". These oils are solvent extracted from the flaxseed and the fatty acids are removed.

Before you buy a raw linseed oil product, verify with the manufacturer that the oil has NOT been refined. A form of refined linseed oil called "Bleached linseed oil" is sometimes available at art stores. This is a refined oil that has undergone additional refining to allow it to flow ameliorate in pigment.

Boiled linseed oil is the course that well-nigh users are familiar with. This oil is commonly bachelor at all hardware outlets today. Boiled linseed oil starts out as refined linseed oil with the fatty acids removed. Metal additives, known as "Siccatives" are added to the oil to speed up the crosslinking process. These additives can exist Cobalt or manganese salts. Zirconium, Calcium, or Zinc salts are too used. In some cases, Lead and barium salts are sometimes added. This allows the oil to cure in 12-24 hours. Boiled linseed oil will never develop the deep red patina that we see on USGI stocks today.

Tung Oil.

Tung oil is probable the beginning oil e'er specifically processed to preserve the woods. The Chinese used it over 2400 years ago to preserve their works. The term "Tung" is a very sometime Chinese term pregnant "of the heart". The leaves of the tung oil tree [Vernicia fordii] have a heart shape to them. At about three years of historic period, the tung tree begins producing nuts which are harvested and pressed for their oil. Each seed produces well-nigh 18-24% oil past weight. This oil is filtered and not refined.

Tung oil undergoes a very different cross-linking process than does linseed oil and has a much faster cure time. Tung oil does not contain linolenic acid and volition not generate the same red patina that raw linseed oil does. Tung oil does incorporate most nine% linoleic acid which tin can provide a slight yellow/red tint with time. However, the color volition not be to the aforementioned degree that linolenic acid does. Tung oil provides a superior water-resistant barrier when compared with Linseed oil.

Tung oil is our recommended oil when a rifle stock is probable to exist in the field for extended periods of fourth dimension. A tung oil finish is durable and has been field-tested for over 2000 years. A finishing wax can e'er be practical to the stock to increase its ability to reject h2o intake in loftier humidity conditions. Be sure to check out our paste wax if you lot plan on operating in wet atmospheric condition for extended periods of fourth dimension.

Like linseed oil, there are many products on the market that call themselves "Tung oil finishes". These are commonly stains and incorporate very little if any real Tung oil. These products are poor substitutes for the real thing. Don't cure your Tung Oil stock in directly sunlight. Surface frosting can occur. A warm place is all that is needed.

Getting Started.

Due northow that you've chosen which oil stop yous wish to use, we'll encompass the procedure of correctly applying that oil to your stock. If you want to offset over with a stripped stock be sure to read the commodity on that process earlier continuing. Nosotros're going to assume that the stock has been stripped or otherwise prepared and sanded by this time. If you lot are applying a touch on-upwardly coat of oil to an existing finish be sure to make clean the surface of the stock well to remove any residues, waxes, or other surface contaminants that might forestall the oil from soaking into the stock.

1Setup a workspace such that your stock can sit without being contaminated with dust or another airborne particulate. Do a final inspection of the stock for any areas that need work. This is the terminal adventure to practise that work without stripping the stock and starting over. If this is a new stock do a trial fit with your receiver and trigger assembly to verify that no areas are binding.

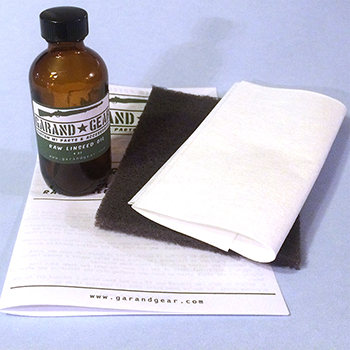

iiOpen your oil kit and remove the contents. There should be a 4oz bottle of oil, a microfiber rag, a 3M finishing pad, and instructions. If yous are sensitive to nut oils be certain to wear appropriate safety gear.

3 The raw oil may be applied as-is or you lot may want to pour some oil bated and thin the first ii coats using 50% oil and l% Mineral spirits or Turpentine. Thinning the first ii coats of oil helps the oil penetrate deeper into the stock.

Rags soaked in drying oils tin self-combust. The curing procedure generates heat. If the rags are tightly packed in an enclosed space they volition grab fire! Always lay your rags out flat in an open and safe area when non in employ! When disposing of rags submerge them in water.

iv Saturate a small piece of lint-gratuitous cloth with the oil and apply liberally to the woods. Completely saturate the wood with the oil. Be sure to oil the entire stock, including the interior surfaces. Hang the stock from a wire to let excess oil to drip from the stock.

v Permit the oil sit for i hour. After an hour utilise the microfiber rag provided to wipe down the unabridged stock and handguards. Whatever oil left on the surface should be wiped abroad. Whatever areas of the wood that are glossy should be wiped downwardly again. Any sleeky areas that develop in the next 24 hours should be wiped down. The stock should never feel tacky or sticky.

6 Allow the stock to sit for 24 hours. After 24 hours rub-downwards the stock using the provided 3M finishing pad. This pace helps assure a smooth finish and removes any raised grain that might take occurred.

[Outset coat of Raw Linseed Oil]

7 Apply 2 boosted coats of the oil over the next two days. Each time wiping off the stock after an 60 minutes and sanding with the finishing pad after 24 hours.

eight Switch to 100% oil now If you had been using a thinned oil in the previous coats. If you've been using 100% oil go along to practice and then.

9 Apply the oil to the stock in the same style equally before. (Note: If the temperature is below 60F, warm the oil container before use. The oil can be heated to 140F (warm to the bear upon) for optimum penetration.) Later 1 hour wipe off any backlog oil. The annoying finishing pad is no longer used at this point.

10 How long to look before reassembly depends upon which oil you used. If you used tung oil then the burglarize should be immune to sit for 2 to three days before handling the stock. Raw linseed oil should be allowed to sit down for 2 to 3 weeks at a minimum at temperatures to a higher place 70 degrees. If the stock is cold it will take longer for the oil to crosslink and cure.

[Raw Linseed Oil Finish on Birch and Walnut]

[1 week later on Finishing]

[Birch – Walnut]

[Final Associates – Raw Linseed Oil – Birch Stock]

Finishing Up:

Northwardatural oil finishes are moderately water-resistant on their own. Tung oil is superior to linseed oil in terms of its ability to repel h2o. If you are going to operate your M1 in high humidity areas you lot will want to utilise a finish wax to the stock after it's cured to limit the uptake of water. If your stock takes in likewise much h2o it can swell slightly and cause the internal components to occasionally rub or bind.

The traditional paste wax (also known as Gunny Paste) that has been used for years was based on beeswax mixed with either tung oil or linseed oil and thinned with a solvent. While effective, this traditional wax has a few pitfalls that should be noted. Exposure to sunlight will break down the beeswax with time and the natural acids volition slowly assault your end — over the years. Museums and antique dealers take long ago moved away from beeswax and switched to microcrystalline-based wax products. We offering a microcrystalline-based end wax that besides blocks UVA/UVB calorie-free earlier it reaches your forest finish. When ultraviolet low-cal strikes a wood finish it breaks united nations-reacted double bonds in the oil. This causes the finish to break down and fade. Our UVA/UVB blocker is designed to absorb much of that energy earlier it reaches your finish.

Our Gunny paste contains no finishing oils allowing it to be applied to any type of woods terminate. Microcrystalline wax is superior to natural waxes because information technology is PH neutral and doesn't contain any acids. Our wax has a melting bespeak of 175F whereas beeswax will become gluey around 144F

[Gunny Paste]

[Gunny Paste]

Applying the wax:

i The stock should be fully cured prior to adding your terminate wax. If you used Tung oil we recommend y'all look at to the lowest degree i week earlier applying the wax. If yous used linseed oil we recommend yous wait one month. If you are going to apply the wax to an existing finish we recommend that yous clean the stock offset to remove any surface contamination or older waxes that might exist present. [Cleaning your M1 Garand]

2 Take a small piece of clean cloth and rub some wax onto it. Using a circular motion apply the wax to the stock. Simply a very small-scale amount is needed. If the stock is broken down utilise the wax to the within areas as well. Pay special attention to areas of end grain. The bulk of wet moves into and out of your stock in these areas.

3 Wait for a infinitesimal or two for the solvent oil to evaporate and using a new make clean piece of fabric, buff out the surface wax with a circular motility. A sparse layer of wax is all that is needed to provide the h2o and lord's day protection we need. Two coats are unremarkably sufficient to protect the stock.

4 We recommend a bear upon-upwardly glaze of wax one time a yr if the rifle is existence used ofttimes.

Welcome to our new website. Returning customers volition need to create a new business relationship when checking out or use the invitee checkout option. -Eric Dismiss

Source: https://www.garandgear.com/m1-garand-new-oil-finish/

0 Response to "what to use on new m1 garand stock"

Post a Comment